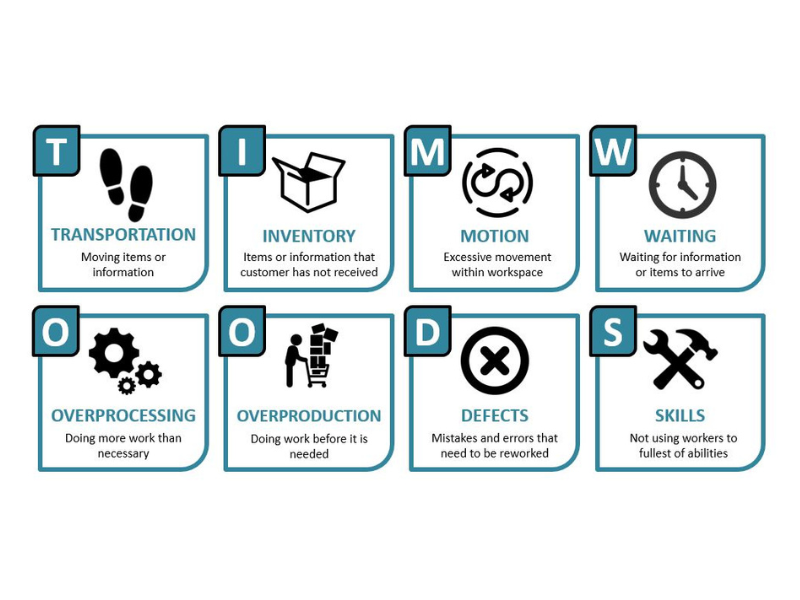

What are the 8 Wastes of Lean?

- 8 Wastes of Lean are identified as Transportation, Inventory, Motion, Waiting, Overproduction, Over-processing, Defects, & Skillset or Non-utilized

talent. - Earlier it was considered as 7 waste of lean manufacturing too.

watch video on : Lean Manufacturing

Examples of 8 Lean Wastes (What does TIMWOOD Stand For?

- To remember 8 waste of lean just need to remember one simple word TIMWOODS, Each letter is representing a waste in industries. These 8 lean wastes are

- T = Transportation

- I = Inventory

- M = Motion

- W = Waiting

- O = Overprocessing

- O = Overproduction

- D = Defects

- S = Skill Set

Another word to remember is the 8 waste of lean can be DOWNTIME

- D = Defects

- O = Overproduction

- W = Waiting

- N = Non-utilized Talent

- T = Transportation

- I = Inventory

- M = Motion

- E = Extra processing

What’s Waste in Process or Lean Manufacturing?

- In simple language, It’s something that adds no values. or

“Our clients would not be happy to pay for any action that we take is called wasteâ€

- as we have unwanted material on the shop floor it consumes more time to find out needed item.

- Would you want ( i mean your customer) to pay for the machine operator’s wages while they sat idle staying for a delivery?

- In a organisation machine was not set correctly, the tool was improper or Operator made a mistakes would you like to pay for that mistakes.

- industries are creating much more inventory then needed, would your customer pay for additional inventory.

- It included these all activities within the cost of your products, either inflating the cost you pay or reducing the profit of the company.

How do you get 8 wastes of lean?

To get rid of the 8 wastes of lean, we’ve to identify all wastes also find our optimum result and implement one of the below methodologies.

- Elimination – Eliminate the waste or process .

- Replacement – replace the process with a better option

- Prevention – Just identify waste in the process and find

- Facilitation

- Detection – Early detection will save lot of time as well as will help you to reduce unnecessary process

- Mitigation

Lets learn and explore more about 8 waste of lean manufacturing

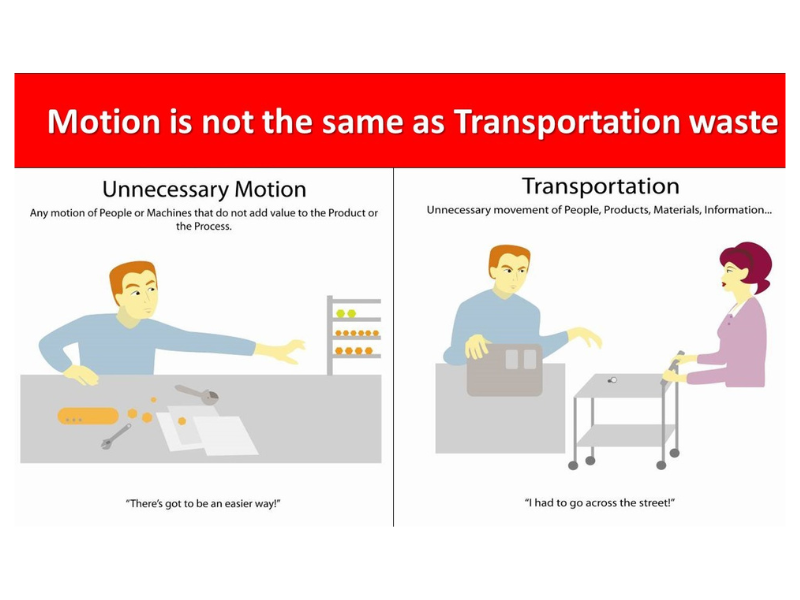

Transportation Waste

- Transportation waste in Lean Manufacturing isn’t adding any value to the product and it directly affects your financial indicator. It can be actually

adding high costs to your business. - Transportation is the movement of materials from one place to another and it doesn’t add any value to the product.

- Your client isn’t willing to pay for this waste.

- Transportation adds no value to the product and you’re paying people to move material from one place to another so this isn’t good for the

association.

Transportation Waste Exemplifications

- Sending unsold products from the store to the storehouse back.

- Ordering parts or products from distant suppliers when near options are available.

- Moving parts from one station to another.

- Moving equipment from one construction location to another.

- In many organizations implementing a lean layout will also help industries eliminate this waste.

Inventory Waste

- Every piece of product tied up in raw material in progress or finished goods has a cost and until it’s really sold that cost is yours.

- Inventory has to be stored, it needs space; it needs packaging and it has to be transported around.

- It has the circumstance of being damaged during transport and getting obsolete.

Inventory Waste Examples

- Excess Raw material, Huge quality of work in progress (WIP), and too much quantity of finished goods (FG).

- Inventory of extra spares and machines in ideal condition.

- All inventory should be optimum and lowest.

Motion Waste

- Unnecessary movements of man or machine. Which doesn’t add any value to the product is known as motion waste.

- Excessive machine movements from the machine start point to the factual work start point.

- All of these nonessential movements bring you time ( money) and cause stress on your workers and machines.

Motion Waste Exemplifications

- Software that requires 10 clicks to start.

- Workers searching for missing tools or instruments.

- The excessive trip between workstations.

Waiting Waste

- Waiting for a delivery from a supplier to come and fix a machine?

- We’ve to spend a huge amount of waiting time for things in our working atmosphere.

- People and processes frequently must wait because the next step in the process is n’t ready for them yet so it’s waste.

Waiting Waste Example

- Waiting for material, Tools, Material handling equipment etc

- waiting for information such as order , planing,

- Emergency room cases waiting for test results in a medical center.

- Farmer is waiting for water for the crop and aeroplane for a gate to open up after landing is also a waste.

Over Production Waste

- If we’ve manufactured any X products and the client doesn’t want it now that’s called Over Production or if the client wants product X-500 Nos and we

manufacture, 550 in that case 50 excess pieces are Over Production. - This is generally because of working with large batches, long lead times, poor supplier relations, and a host of other reasons.

- Overproduction leads to high levels of inventory.

- The aim should be to make only what’s needed when it’s needed by the client, the philosophy of Just in Time (JIT) or Continuous Flow ( Single Piece

Flow) still multiple companies work on the principle of Just in Case! (JIC).

Over-Production Waste Examples

- Production is further than client demand.

- Huge meals in restaurants.

- Hospitals with more beds than the community needs.

- Overstaffed retail stores

Over Processing Waste

- Over-processing is doing further than the client wants and giving money for the product or service.

- now and then Over Processing waste generates due to improper methods, oversize equipment, working to patience that is too tight, performing

processes that aren’t needed by the client, and so on. - All of these things cost us time and money.

Over Processing Waste Exemplifications

- Doing any job again and again which is not adding value, such as repairing of one motor again and again is pure waste.

- Recycling in any industries is a type of pure waste.

Defects Waste

- Defects hide multiple other problems and wastes.

- Quality errors that cause defects invariably cost you far more than you expect.

- Every imperfect item requires rework or substitute, it wastes resources and materials, it can lead to misplaced clients.

- We’ve to work on defect prevention rather than defect detection.

- Implementation of Poka-Yoke systems and automation can help to prevent defects from occurring.

- We can use Jidoka Automation for defect prevention purposes.

- We also need to implement standard operations procedures ( SOP) and training to ensure that the correct methodologies are accepted and norms

achieved. - I directly related the defect to the Cost of Poor Quality

Defects Waste Exemplifications

- Software with bugs is a defect that has to bere-coded.

- Misdiagnoses in healthcare lead to nonessential tests or treatment.

- Products that are packed to the wrong address are also a disfigurement.

- Manufactured items that don’t meet the client’s specifications are defects.

Skill- Set (non-utilized talent) Waste

- Skill-set or non-utilized talent is recently added waste in Lean and it costs you money.

- Not completely utilized people represents the waste of talent present in multiple associations.

- Because operators are close to their processes daily, they can frequently recognize problems or chances that staff or superiors just don’t see, but the

workers may noway be asked for their input. - They may also have outside talents that aren’t formally part of their assigned jobs but could be of use.

- The recommendation? Value people for their brains, not just their brawn.

Skill- Set (non-utilized talent) Waste Exemplifications

- Intentionally we aren’t including any competent employees or any department or section is also an illustration of non-utilized talent.

- If we don’t give our workers any chance for process improvement or any suggestion about improvement also comes under skillset waste.

The Benefit of Elimination of Wastes

- It Improves efficiency and effectiveness

- Increase the productivity of production processes

- It’ll increase the performance of factory indicator OEE ( Overall Equipment Effectiveness)

- It creates a safer working atmosphere for all workers.

- Reduce downtime

In conclusion, the 8 Wastes of Lean Manufacturing, often remembered using the acronym “DOWNTIME” (Defects, Overproduction, Waiting, Non-Utilized Talent, Transportation, Inventory, Motion, and Extra-Processing), are vital concepts for organizations seeking to optimize their operations.

These wastes represent various forms of inefficiencies, resource misallocation, and added costs that can erode profitability and customer satisfaction. By identifying and systematically eliminating these wastes, companies can streamline their processes, reduce lead times, enhance product quality, and minimize overall production costs.

Embracing the principles of lean manufacturing and actively working to reduce these Eight Wastes can lead to increased competitiveness, improved customer value, and sustainable success in today’s dynamic business landscape. I hope you got detail overview for 8 waste of lean manufacturing