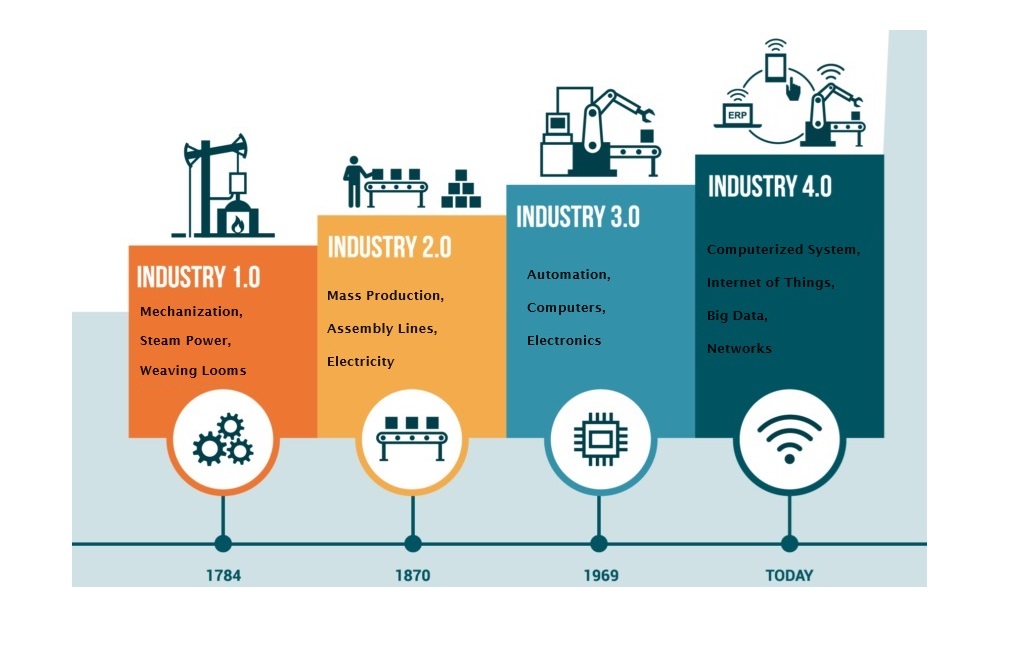

Industry 4.0

Meaning of industry 4.0 The term “Industry 4.0” is used for the fourth industrial revolution. This revolution is characterized by the integration of advanced digital technologies into manufacturing and production processes, leading to the creation of smart factories. These technologies include the Internet of Things (IoT), big data analytics, artificial intelligence (AI), cloud computing, and

Read More