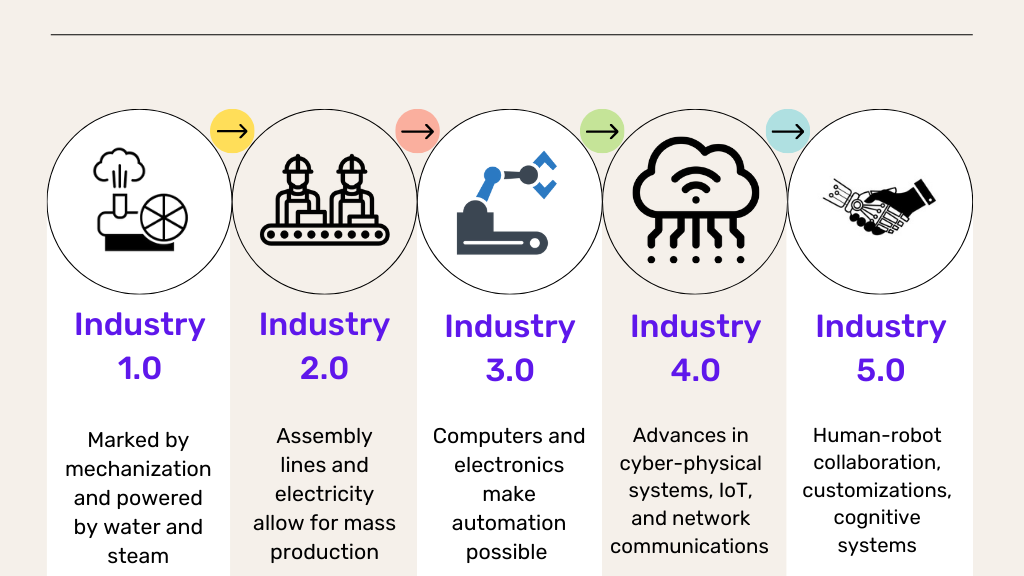

Welcome to the dynamic era of Industry 5.0, where technology seamlessly integrates with personalization and sustainability. As we move beyond the automated efficiency of Industry 4.0, Industry 5.0 introduces a collaborative relationship between humans and machines, aiming to enhance creative and cognitive tasks. Industry 5.0 seeks to reintegrate human skills and capabilities into the manufacturing and production processes. This five-generation leap in the manufacturing sector emphasizes not just automation, but also the importance of human touch and environmentally friendly production processes. Here is a glimpse of how this new era is set to reshape manufacturing, making it more agile, adaptable, and aligned with human values.

Key Features of Industry 5.0

- Human-Machine Collaboration: Industry 5.0 emphasizes collaborative robots (cobots) and intelligent systems that assist and augment human workers. These technologies are designed to work alongside humans, enhancing their capabilities rather than replacing them.

- Personalization and Customization: Industry 5.0 aims to meet the growing demand for personalized products and services. By integrating human creativity into the manufacturing process, companies can offer highly customized solutions tailored to individual customer preferences, thus enhancing customer satisfaction and loyalty.

- Sustainability and Ethical Practices: The new industrial paradigm strongly emphasizes sustainable practices and ethical considerations. This involves utilizing eco-friendly materials, minimizing waste, and guaranteeing fair labor practices.

- Advanced Technologies: While human-centric, Industry 5.0 still relies heavily on advanced technologies such as AI, IoT, 3D printing, and augmented reality (AR).

- Reskilling and Upskilling: With the integration of new technologies, there is a growing need for a workforce equipped with the necessary skills to operate and collaborate with these systems. Industry 5.0 prioritizes ongoing learning and development, ensuring that employees are equipped to adapt to new roles and responsibilities.

The Impact of Industry 5.0

The advent of Industry 5.0 is set to revolutionize various sectors, from manufacturing and healthcare to retail and services. Here’s how:

- Manufacturing: In manufacturing, the synergy between humans and machines will lead to the creation of more innovative products, improved production efficiency, and the ability to respond swiftly to market changes. Customization will become the norm, and production lines will be more flexible and adaptive.

- Healthcare: In healthcare, Industry 5.0 can lead to advancements in personalized medicine, where treatments are tailored to the genetic makeup of individual patients. AI and robotics will assist healthcare professionals, improving diagnosis accuracy and surgical precision.

- Retail: The retail sector will benefit from enhanced customer experiences through personalized shopping experiences and products. Combining AI-driven insights with human creativity enhances the interactivity and engagement of retail environments.

- Services: In the service industry, AI and human collaboration can enhance customer service, streamline operations, and improve overall efficiency. Chatbots and virtual assistants, augmented by human oversight, will provide more effective and empathetic customer interactions.

Challenges and Considerations

As with all major transitions, Industry 5.0 presents its unique set of challenges alongside its opportunities. Companies navigating this evolution must weigh these elements carefully while planning their growth and operational strategies.

- Integration of Technologies: Seamlessly integrating advanced technologies with human-centric processes requires significant investment and strategic planning. Companies must ensure that the technologies they adopt complement and enhance human capabilities.

- Workforce Transformation: Reskilling and upskilling the workforce to adapt to new roles is crucial. This requires collaboration between industry, educational institutions, and governments to create training programs that equip workers with the necessary skills.

- Ethical and Social Implications: The increased reliance on AI and automation raises ethical questions regarding privacy, data security, and the potential for job displacement. Companies must navigate these issues with transparency and responsibility.

- Sustainability: It is crucial, requiring a balance between economic growth and environmental responsibility. Industry 5.0 must focus on eco-friendly practices and create solutions that reduce environmental impact.

Future of Work in Manufacturing

The advent of Industry 5.0 is not just revamping our manufacturing technologies but also reshaping the essence of workplace dynamics. Promoting the seamless integration of smart technology and human intelligence in manufacturing will transform roles, skill requirements, and work environments.

Human-Machine Collaboration

- Cognitive Assistance: Robots equipped with AI can analyze data and provide insights, while humans make strategic decisions based on that information.

- Physical Cooperation: Cobots (collaborative robots), which are designed to physically interact with humans in a shared workspace, help by performing strenuous or precision-required tasks, reducing workplace injuries and increasing productivity.

Reskilling the Workforce for Industry 5.0

- Technical Proficiency: As digital tools proliferate, understanding data analytics, machine operation, and maintenance of sophisticated systems become essential.

- Soft Skills: Creative thinking, complex problem-solving, and interpersonal skills will be just as important, as these are the areas where human workers excel over machines.

Flexibility and Remote Work Trends

- Remote Operations: Engineers might use real-time data and simulations to troubleshoot problems from afar, enhancing operational efficiency without compromising their work-life balance.

- Customizable Work Hours: Flexible scheduling will cater to a globally distributed workforce and varying customer demands, making manufacturing a more dynamic field.

Embracing Industry 5.0 for a Transformative Future in Manufacturing

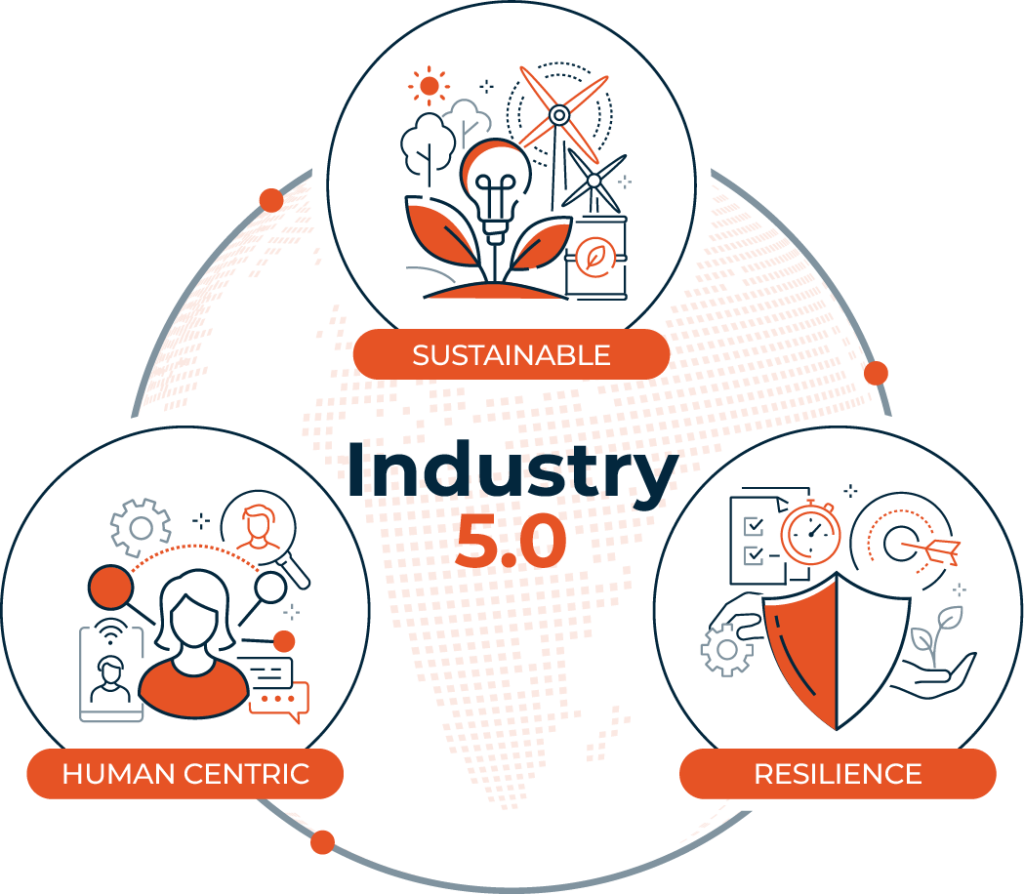

The advancement towards Industry 5.0 presents a transformative future for manufacturing sectors worldwide. This new evolution doesn't just focus on enhancing productivity and efficiency through technology but is strategically oriented towards creating a human-centric, sustainable, and resilient workplace. Embracing Industry 5.0 requires a shift in mindset at all levels—from ground-floor operators to executive leaders.

As businesses transition into Industry 5.0, there will be an increased emphasis on:

- Customization and high-level personalization in production.

- Collaboration between humans and machines to solve complex challenges.

- Ethical considerations and sustainable practices that align with global standards.

The successful integration of this progressive era will significantly depend on the ability of businesses to adapt and evolve, ensuring that technology augments human capabilities rather than replacing them. Embrace Industry 5.0 with open arms and ready minds, for a future where technology and humans operate in harmony, leading to unprecedented levels of innovation and efficiency in manufacturing.