what is takt time?

Takt time is often used in Lean Manufacturing, a methodology focused on eliminating waste and optimizing efficiency. It helps align production processes with customer demand, preventing overproduction and minimizing unnecessary inventory.

This concept ensures a smoother workflow, allowing companies to meet customer expectations while maximizing resource efficiency.

Additionally, takt time is not exclusive to manufacturing; it can also be applied in service industries. Whether in a call center or healthcare facility, understanding and implementing takt time principles enhance overall efficiency and customer satisfaction by aligning service delivery with demand.

Takt time is a crucial concept in manufacturing and production management. It represents the available production time divided by customer demand, determining the time allowed to produce a single unit or deliver a service. In simpler terms, it is the pace at which a product or service needs to be produced or delivered to meet customer demand efficiently.

Purpose of lean tools is to improve takt time.

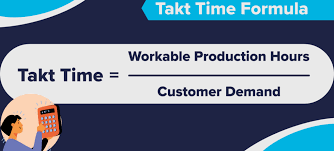

Takt time formula

The formula for calculating Takt Time is straightforward and involves two key variables: Available Production Time and Customer Demand.

The takt time calculator for calculating Takt Time is straightforward and involves two key variables: Available Production Time and Customer Demand.

- Available Production Time: Refers to the total time a production process or operation is available for work. It is typically measured in hours or minutes.

- Customer Demand: Represents the total quantity of units or services that customers require within the specified time period.

By dividing the Available Production Time by Customer Demand, you get the Takt Time, which indicates the time allowed for producing a single unit or delivering a service to meet customer demand efficiently.

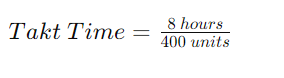

For example, if a manufacturing facility operates for 8 hours a day (8 hours of Available Production Time) and the customer demand is 400 units, the Takt Time would be calculated as follows:

This calculation would result in a Takt Time of 0.02 hours per unit. This metric is valuable in Lean Manufacturing and other production settings, helping organizations synchronize production with customer demand to optimize efficiency and reduce waste.

Learn More: How Overall equipment Efficiency will improve takt time ?

Takt time vs cycle time

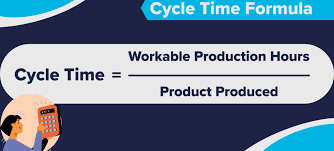

- Definition: Cycle time is the total time it takes to complete a task, process, or production cycle. It includes all the individual steps from the beginning to the end of a process, encompassing both the time the item spends being worked on and any idle time in between.

- Purpose: Cycle time provides a comprehensive view of the overall efficiency and duration of a process. It helps identify bottlenecks, delays, or areas for improvement within the production cycle.

- Formula: Cycle Time = Process End Time - Process Start Time

Key Differences:

- Focus: Takt time focuses on aligning production with customer demand to prevent waste and optimize efficiency. Cycle time, on the other hand, looks at the total duration of a specific process or production cycle.

- Calculation Basis: Takt time is calculated based on customer demand and available production time. Cycle time is calculated based on the total time taken for a specific process or cycle to complete.

- Customer-Driven vs. Process-Driven: Takt time is customer-driven, ensuring that production meets the rate of customer demand. Cycle time is process-driven, providing insights into the efficiency and duration of a specific production or operational process.

In summary, while Takt time and cycle time are related to time in a manufacturing setting, they serve different purposes. Takt time ensures that production meets customer demand efficiently, while cycle time provides a broader perspective on the overall duration of a specific process. Understanding and optimizing both metrics are essential for improving efficiency in manufacturing operations.

In conclusion, Takt Time emerges as a pivotal concept in modern manufacturing and beyond. By synchronizing production with customer demand, businesses can achieve higher efficiency, reduce waste, and enhance customer satisfaction. Whether in traditional manufacturing or service industries, understanding and implementing Takt Time principles foster a streamlined workflow and resource optimization. Continuous improvement through Takt Time not only ensures competitiveness but also resilience in the face of dynamic market demands. As industries evolve, embracing Takt Time remains a cornerstone for staying agile, efficient, and customer-centric.

Read More Do you know time Management will imrpove your personal Efficiency ?

How one piece flow will imrpove takt time?

One-piece flow and takt time are both concepts associated with lean manufacturing, aimed at improving efficiency and reducing waste in production processes. Let's explore how one-piece flow can contribute to improving takt time

One-piece flow emphasizes a continuous and smooth flow of work from one process to another. This minimizes waiting times between processes that typically occur in batch production.

In a one-piece flow system, any issues or defects can be identified immediately as each unit is processed individually. This allows for quick resolution of problems, preventing the accumulation of defects that might occur in batch production.

Faster issue resolution contributes to maintaining the overall pace of production in alignment with the takt time.

One-piece flow inherently balances the workload across different workstations because each workstation is continuously working on one unit at a time.

Balancing the workload ensures that no single workstation becomes a bottleneck, preventing delays that could disrupt the takt time.

FAQ

- What is the difference between takt time and cycle time? Takt time is customer-driven, aligning production with demand, while cycle time represents the total time to complete a task or process.

- How can small businesses implement takt time? Small businesses can scale and adapt takt time principles to fit their operations, fostering efficiency and sustainability.

- What challenges are associated with takt time? Variability in demand is a common challenge, and strategies for handling fluctuations are essential for successful takt time implementation.

- Are there software tools for managing takt time? Yes, various software tools are available to assist in implementing and managing takt time. Choosing the right software is crucial for maximizing its benefits.

- How has the COVID-19 pandemic impacted the use of takt time? The pandemic has highlighted the importance of adaptability, and takt time proves to be a valuable tool in responding to changes in demand and ensuring resilience in manufacturing.