f you’re looking for a way to improve the efficiency of your workplace, you might consider implementing the 5S methodology. This method has been used for decades in manufacturing and other industries to streamline processes and reduce waste. In this article, we’ll explain what the 5S methodology is, how it works, and how you can implement it in your own workplace.

What is the 5S Methodology?

The 5S methodology is a system for organizing and optimizing the workplace. It originated in Japan and is based on five principles, each of which begins with the letter “S”:

Sort

The first step in the 5S methodology is to sort through everything in the workplace and remove anything that is not needed. This helps to eliminate clutter and ensure that only necessary items are kept in the workspace.

Set in Order

Once everything has been sorted, the next step is to organize the remaining items in a logical manner. This might involve grouping similar items together, labeling everything clearly, and ensuring that frequently used items are within easy reach.

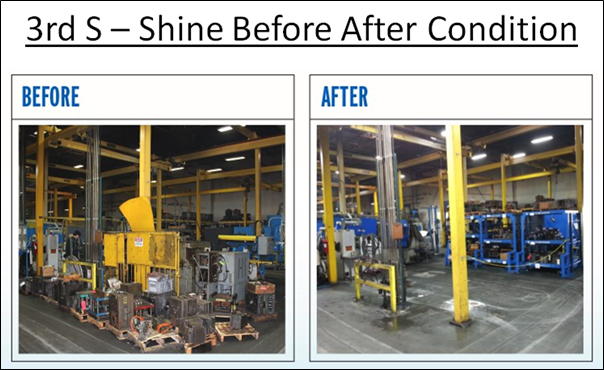

Shine

The third principle of the 5S methodology is to keep everything clean and tidy. This involves regular cleaning and maintenance of equipment, as well as ensuring that work areas are free of debris and clutter.

Standardize

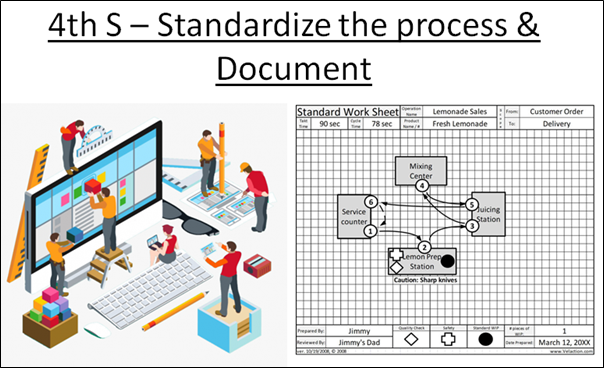

The fourth principle of the 5S methodology is to establish clear standards for everything in the workplace. This might involve developing standard operating procedures for certain tasks, creating visual aids to help employees remember important information, or establishing guidelines for how equipment should be used and maintained.

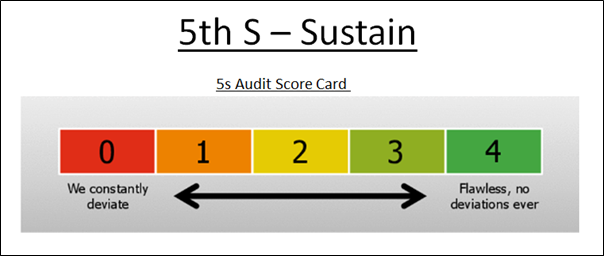

Sustain

The final principle of the 5S methodology is to sustain the improvements that have been made. This involves creating a culture of continuous improvement in which employees are encouraged to identify opportunities for further optimization and are empowered to make changes as needed.

How Does the 5S Methodology Work?

The 5S methodology is designed to improve workplace efficiency by eliminating waste and optimizing processes. By following the five principles outlined above, companies can reduce the time and resources required to complete tasks, as well as improve safety and quality.

One of the key benefits of the 5S system is that it is highly adaptable. It can be used in a wide range of industries and can be applied to virtually any process or workflow. Additionally, because the methodology emphasizes continuous improvement, it is well-suited to companies that are constantly looking for ways to optimize their operations.

Read Blog on: 5s Sustain – is a problem

How to Implement the 5S Methodology in Your Workplace

If you’re interested in implementing the 5S methodology in your workplace, there are a few key steps you should follow:

1. Get Buy-In from Employees and Management

Before you begin implementing the 5S methodology, it’s important to get buy-in from both employees and management. This will help ensure that everyone is committed to the process and that there are no roadblocks or pushback during implementation.

2. Conduct a Workplace Assessment

The next step is to conduct a thorough assessment of your workplace. This might involve walking through each area and identifying areas where improvements can be made, such as reducing clutter or optimizing workflow.

3. Develop a Plan

Once you have identified areas for improvement, the next step is to develop a plan for implementing the 5S methodology. This might involve creating a timeline for when each principle will be implemented, identifying the resources that will be needed, and establishing clear goals and metrics for success.

4. Train Employees

It’s important to train employees on the principles of the 5S methodology and how it will be implemented in your workplace. This might involve providing hands-on training, creating training materials such as videos or manuals, or bringing in outside experts to lead training

The 5S System is a key aspect of Lean Manufacturing, and it refers to a set of five principles that serve as the foundation for continuous improvement. The 5S System is an organized approach to workplace management that helps to create a clean, efficient, and safe working environment. The five principles of the 5S System are:

Sort (Seiri):

This involves separating needed items from unneeded items and removing the unneeded items from the workplace. This helps to reduce clutter and increase efficiency.

Simplify (Seiton):

This involves arranging the remaining items in the workplace in a way that is easy to access and use. This helps to reduce waste and increase efficiency.

Shine (Seiso):

This involves cleaning the workplace and maintaining it in a clean and organized manner. This helps to prevent waste, reduce the risk of accidents, and improve overall morale.

Standardize (Seiketsu):

This involves establishing standard procedures and processes to ensure that the workplace remains clean and organized. This helps to prevent waste, reduce the risk of accidents, and increase efficiency.

Sustain (Shitsuke):

this involves maintaining the standards established in the previous 4S steps and continuously improving the workplace. This helps to prevent waste, reduce the risk of accidents, and increase efficiency. The 5S System is a key aspect of Lean Manufacturing because it helps to create a clean, efficient, and safe working environment.

By following the five principles of the 5S System, organizations can improve their processes, reduce waste, and increase efficiency.

Additionally, the 5S System in manufacturing provides a framework for continuous improvement, enabling organizations to continuously improve their processes and achieve long-term success

Read more : Do you know you can beat compitition by implemeint 5s –

Our Clients