The 7 waste of lean manufacturing are a set of specific inefficiencies that can occur in any production process.

Identifying and reducing these wastes is a key aspect of Lean Manufacturing and is critical to improving process efficiency and reducing costs. The Seven Wastes are:

Lean Manufacturing is a philosophy and management approach aimed at reducing waste and improving efficiency in production processes. It emphasizes the elimination of non-value-added activities to optimize operations and enhance overall customer value. One of the fundamental principles of Lean Manufacturing is the identification and elimination of the 7 wastes, also known as the “7 Mudas.” In this article, we will explore these 7 wastes, provide examples, and discuss strategies to minimize them in various industries.

Overview of the 7 Wastes of Lean Manufacturing

Lean Manufacturing identifies seven key wastes that hinder operational efficiency. By understanding and addressing these wastes, organizations can streamline their processes and improve overall productivity. Let’s take a closer look at each waste:

Following are the 7 waste of lean

1. Inventory:

This refers to any inventory that is not needed to meet customer demand. This can result in increased storage costs and decreased flexibility.

Inventory has value on the balance sheet of the company but having inventory more does not add value to your customers.

A customer will not pay you more for your product if you have more goods, and they will not pay you less if you can meet the expectations of what they are bringing with a small inventory.

While inventory will often be needed (e.g., as a refuge for compliance with different customer needs), it should always be treated as waste and minimized.

Watch vidoe on intventory reduction – How to reduce inventory?

2. Waiting time:

This refers to the time spent waiting for resources, materials, or approvals to continue with a process. This can result in increased lead times and decreased process efficiency

A waiting period is an idle time spent by employees waiting for something to happen. Usually, they will be waiting for another task to complete the task or waiting for the machine to complete its cycle. While waiting, the employee does not add value to the product, so waiting is a waste.

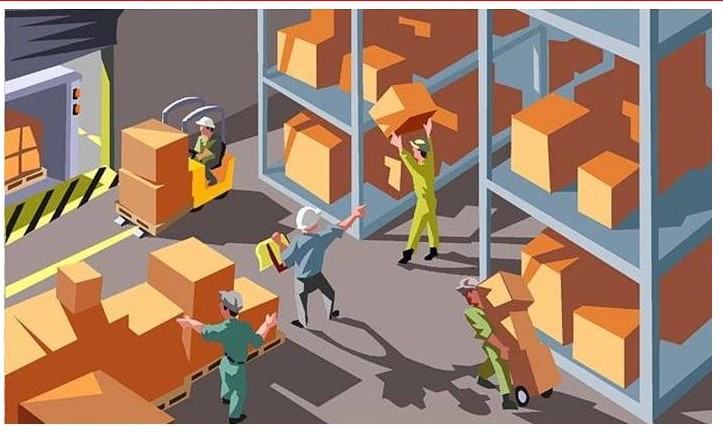

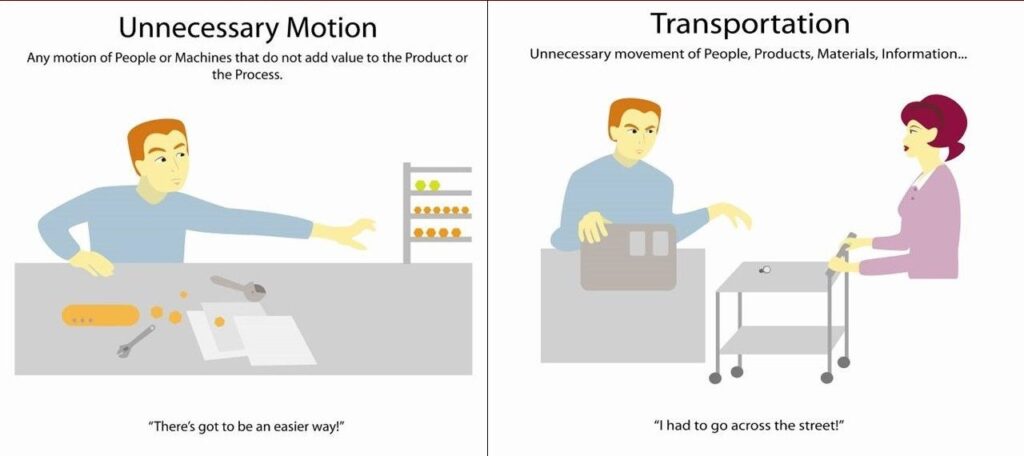

3. Movement:

In most jobs, employees will spend most of their time travelling. Going from one part of the production line to the other, going back to collect or deliver building materials, or walking around work cells. When you leave, employees do not charge value to customers, so the move is wasteful.

4. Transportation:

The closest thing to movement is travel time. This is time spent moving goods and products around the plant or from place to place – a necessity if you have a large site or a wide variety of operations, but it does not increase the value of the product and therefore is wasted.

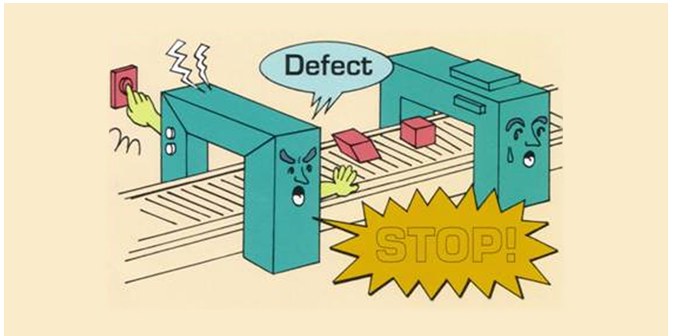

5. Mistakes or defects:

Ask the majority of waste workers and they will talk about dumping or disability. Corruption and degradation do not add value to consumer products and should be treated as waste.

6. Excessive processing:

Production processes often involve processes that do not add value to a product, and we should view those processes as waste and try to eliminate them. Examples of this type of debris include excessive testing measures, continuous installation or sub-assemblies that need to be removed later in the process, and finishing parts (where the excavation or cutting process caused the burr to be rearranged to prevent the original burr).

7. Overproduction:

Overproduction is just the opposite of time. Overproduction produces more of what is needed sooner than necessary. Overproduction often manifests itself as continuous job creation. Overproduction is often the result of large clusters and unequal processes and is somehow the worst type of waste as it is associated with increased inventory, and bulk transportation, and is often overused.

Identifying wasteful activities is something that should start at the top of the company. Often, high-level management has a broader view of all processes. In this way of thinking, we can say that they manage a portfolio of different activities, functional areas, and projects, and it is their responsibility to create processes and spread a culture of sustainable development.

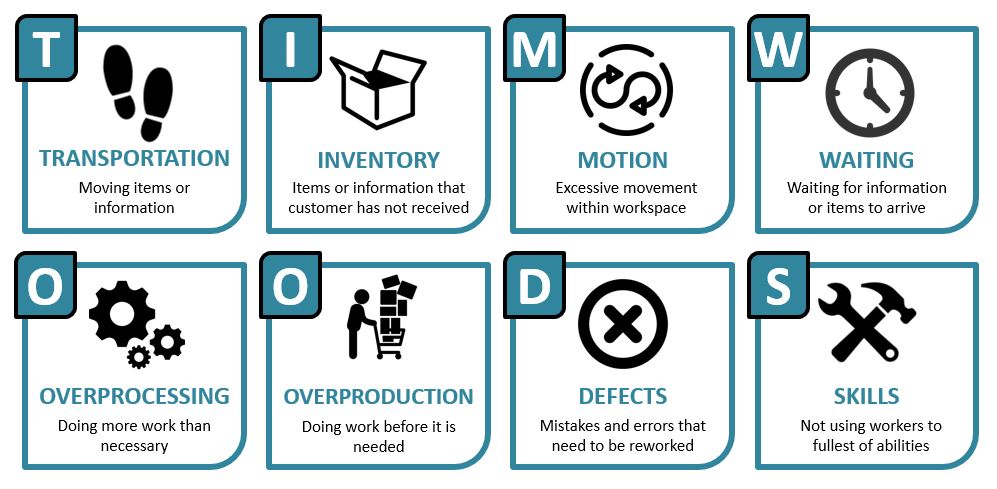

TIMWOOD” is an acronym in Lean Manufacturing that stands for:

T – Transportation

I – Inventory

M – Motion

W – Waiting

O – Overprocessing

O – Overproduction

D – Defects

TIMWOOD is used to identify and eliminate waste in a manufacturing process, with the goal of improving efficiency and reducing costs. By reducing or eliminating these wastes, companies can streamline their operations, increase productivity, and enhance customer satisfaction.