What is 5s implementation?

- How to start 5s Implementation? 5S Methodology was developed in Japan and it’s a system for organizing spaces so work can be performed efficiently & effectively safely it’s a fundamental tool of Lean Manufacturing

- It’s a system for organizing space so work can be performed efficiently & effectively with safety.

- Now and then it’s also referred to as a good housekeeping practice but both are different things

Benefits of 5S Quality 5s meaning | What does the 5S Stand for? |How To Start 5S Implementation

1. History:

- This methodology was developed in Japan by two gentlemen, Osada, and Hirano who structured a framework for implementing their philosophy.

- Some say that the principles of this Methodology came from Henry Ford.

- Henry Ford used the CANDO system (CANDO stands for Cleaning up,

- Arranging, Neatness, Discipline, and Ongoing Improvement) before the development of this Methodology.

2. Benefits of 5S

- Increase productivity through effectiveness

- Reduction in delays

- Improved

3. Quality

- Improve in Safety

- Set-up times reduced

- Morale & MotivationIncrease

- Lessstress for operators

- Safer work atmosphere

- Improvement in the regular process

4. 5S Meaning| What does the 5S stand for?

- It stands for five Japanese wordsSeiri, Seiton, Seiso, Seiketsu, and Shitsuke.

- English Meaning of the above Japanese words are

- (1S) Seiri → Sort or Tidiness

- (2S) Seiton → Set In Order or Orderliness

- (3S) Seiso → Shine (Clean) or Cleanliness

- (4S) Seiketsu → Standardize or Standardization

- (5S) Shitsuke → Sustain or Discipline

5. how to start 5s implementation?

- Now we will see the implementation of 5S step by step.

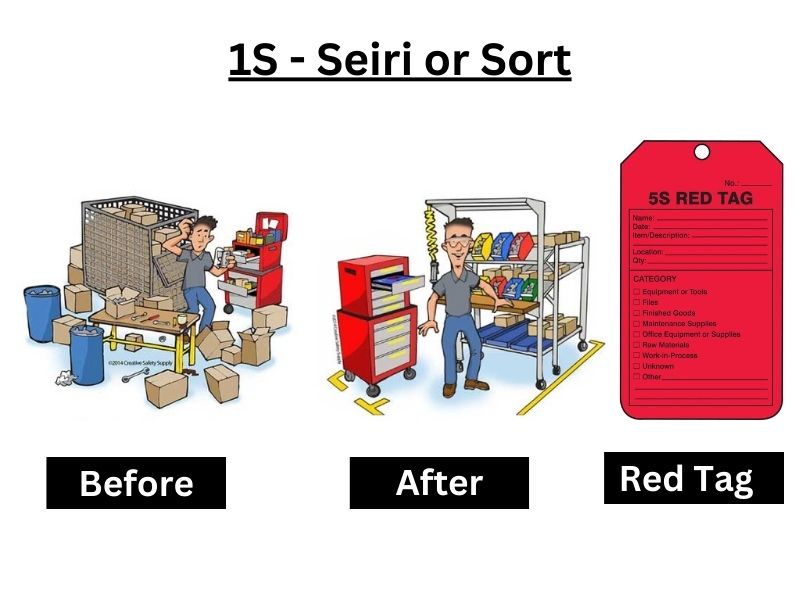

(1) 1S-Seiri or Sort

- The first step is to Sort in this Methodology.

- ” Sorting” means sorting everything in each work area that we need and what we do not need.

- Sort means removing nonessential items or materials from a workspace.

- Keep only what’s actually needed every day from the workspace.

- Materials, equipment, instruments, or any things that aren’t constantly- used should be moved to a separate, common warehouse area called Red Tag

Zone. - Items that aren’t used should be removed or recycled.

- Please don’t keep anything in your plant just because it might be used in the future.

- The whole team should spend a few hours going through the entire area (inside closets, under and behind machines. Everyplace!!!)

- All obvious scrap should be put in the scrap area/ box

- All unidentified things should be put in the “ Red label”/ quarantine area.

- Only items that are needed should remain.

Steps for Sorting

- Cleaning

- Classifying

- AssignResponsibility

- Red Tagging of nonessential things

- Recycling or Reassignment of things arrived in Red Tag Zone.

- For a better understanding of how the below picture of the Before-After comparison of Work Place and the Red Tag

5S Exemplifications

(2) 2S-Seiton or Set In Order

- Set in order is for organizing the items or materials at the plant.

- “ DefinePlace for Everything and Put Everything in its place”

- We can use a systematized plant more efficiently and effectively

- To arrange all necessary items for the economy of movement.

- Put things as per the frequency of use.

- Provide a safe warehouse – heavy items at a low rank, light items at a height.

- If any item is missing also we can fluently find out it

Basic Principles of Set-in Order

- The items that are used really constantly should be kept nearer to where they’re used.

- Items that are used really multiple times should be kept far compared to constantly used things.

- After completion of work keep things in their defined place.

- If several things are used together, also store them together.

- For illustration, a welding rod is used with a welding machine also both should be kept together.

- Store things in a place where people can fluently find

- Identify all items ( including fixtures, gauges, tools, jigs, molds, etc.) and mark identification symbols on them so we can fluently identify and return

them to their identified warehouse place. - For better understanding refer to the below picture of the sort in order.

5S Housekeeping

(3) 3S-Seiso or Shine (cleaning)

- After Sort and Set In Order, the plant requires regular

- Shine is used for regular cleaning of the plant, tools, and equipment

- Cleanliness makes defects easier to detect.

- Better client satisfaction

- Creates a better working atmosphere

- It isn’t just the job of a housekeeper, it’s everyone’s responsibility

- Every plant should have a person, or group, assigned to clean that area.

- The best approach is that those who work in a plant are also responsible for cleaning that area.

(A) Cleaning is an ongoing process

- Define and document

- Decide Who, What, When, Where, How, etc …

- Who’s responsible for cleaning

- What needs to be cleared and where

- When it’ll be done

- How is it to be done and which tools demand

- For better clarity related to the below picture in which we can fluently see the comparison of the plant before and after cleaning.

(4) 4S-Seiketsu or Standardize

- After completion of Shine or Clean, Standardize will come.

- Standardizing means documenting each necessary process or activity.

- Standardizing can turn Good Practices into Good Habits.

- By developing standards for process, all person knows what to do, how to do it, when to do it, where to do it, etc.

- Give awareness about standardizing to all persons.

- It’ll help them to remember the new standards and it encourages them to do the same.

- We can use tags, symbols, posters, and banners for standardization.

(A) How do we Standardise?

- Document standard ways of working ( SOPs),. Process Flow Diagram or Flow Chart

- Standardize labeling, signage, and Flow

- Audits

(B) Standard Work

- Document the current agreed way of doing a process

- Provides a baseline for improvement

- Reduces variation between people/ shifts

(C) Standardized flow and Signage

- Common methodologies to show where the work enters and leaves the cell.

- Standard methodologies for identifying components and tool places

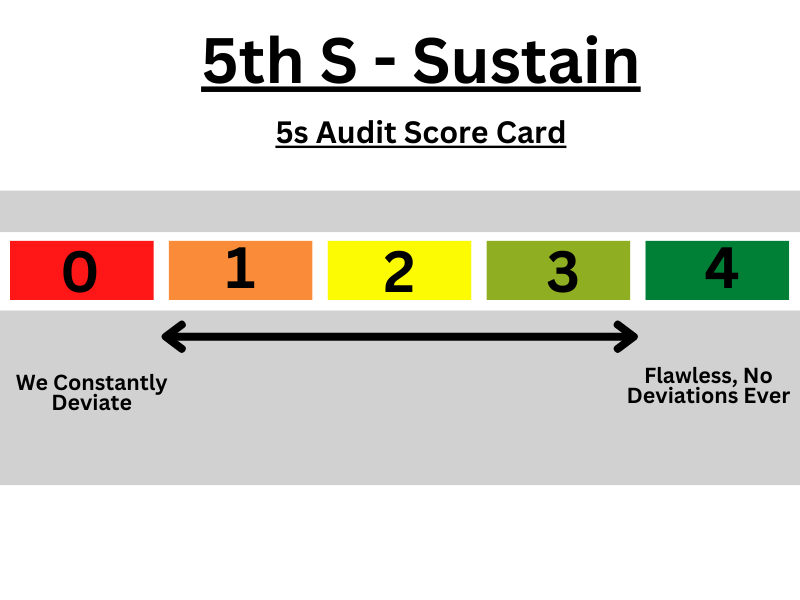

(D) 5S Audit

- Independent audit of an area

- Capture current state – Use color photos

Document

(5) 5S-Shitsuke or Sustain

- Sustain needs to maintain 5S within the plant or work pace.

- Keep a record of progress with evaluations, communication, and training-related activity.

- Assign continuing responsibility.

- Sustain keeps watch on ongoing training activity and maintains the Established System.

- Maintaining Audits

- Maintaining cleaning

- Making it “ A Way of Life”.

you can also avail 5s Training from us

Top Management’s Support needed to Sustain

- We can sustain our commitment to the 5S methodology in our industry with the help of Top management’s support.

- Top Management should be involved in these activities similar as

- Conducting inspections on a random basis for checking the sustenance of the system

- Establish a proper communication channel from top to bottom and bottom to top.

- Provides training to workers.

- Participation in promotional events at the plant.

- What Is 5s System & why 5s fail What Is 5s System Honest Video, how to start 5s implementation?

- How can you beat covid-19 by implementing 5S Japanese Practice

- How to Reduce Inventory, Inventory Management Tool & Tactics

- What Is Kaizen, What Is Kaizen With Example, non-value added activity, Kaizen Muda

- One Point Lesson | One point lesson types & example |TPM one point lesson | OPL explain

- Learn The 7 Wastes Of Lean The 7 Wastes of Lean for Frontline Kaizen -Lean Manufacturing Training

- Overall Equipment Efficiency What Is OEE – Overall Equipment Effectiveness Solution

- What is Lean Manufacturing | Lean tool crash course | Lean Manufacturing in 5 min | Lean in Hindi

- 8 Wastes of Lean, lean manufacturing

- Lean Implementation, the benefit of Lean, lean practice, and how to implement lean tools